Over 60 Years of Innovation

SEKISUI KYDEX has pioneered durable, fire-rated polymers that do not contain plasticizers. As part of SEKISUI Chemical, SEKISUI KYDEX remains focused on innovation and exceeding customers’ expectations.

Foundations

The SEKISUI KYDEX story began more than 60 years ago, in 1965, when KYDEX® 100 was invented near Philadelphia at the Rohm & Haas Co. At its outset, this high-impact, fire-rated, and acrylic-modified PVC thermoplastic sheet proved ideal for hard-to-form parts for a wide range of applications, including aircraft components and mass transit interiors. It quickly gained a reputation as an extremely durable, chemical-resistant, and fire-retardant polymer innovation.

New Beginnings

In 1987, KYDEX® Thermoplastic production assets and the brand name were purchased by a small team of ex-Rohm & Haas employees, who started the Kleerdex Company in Bloomsburg, Pennsylvania. In 1990, the company was acquired by SEKISUI Chemical.

Driven by Innovation

The team that purchased KYDEX® Thermoplastics recognized the product’s profound potential. Their entrepreneurial spirit and unfailing resolve to expand the product line and deliver more than our customers could imagine drove their early success and continues to influence today’s product lines.

30 Years of Achievement and Growth

More about Our Process

Discover how decades of innovation, dedication, and entrepreneurial spirit have shaped the evolution of this industry-leading material.

—

Roots in transportation

After the production assets were installed in Bloomsburg, the team worked diligently to quickly expand the portfolio beyond the workhorse KYDEX® 100, which was already widely used by domestic airlines for aviation interior components. In 1990, the team invented KYDEX® 6200 for mass transit interior components to meet newly established low-smoke regulations set forth by the Federal Transit Administration.

Soon after, the aviation portfolio grew with KYDEX® 657 and KYDEX® 6565 to meet and exceed the Federal Aviation Administration’s (FAA) more stringent regulations for heat release and smoke density.

—

Innovation through process

Excellence in manufacturing, customer service, and design is just a few foundations that have made SEKISUI KYDEX a success. Through its early adoption of Kaizen methodology and continuous improvement, the company has always provided best-in-industry lead times and low minimum order quantities. In 1993, SEKISUI KYDEX was one of the first plastic manufacturers in North America to achieve ISO 9001 certification.

—

Innovation through design

Since its early days, SEKISUI KYDEX has been known for its refined, integral color. The original nine-color palette quickly grew to 33 standard colors and now includes over 4,000 library colors with virtually unlimited color matching capabilities. Over the decades, design capabilities have grown with the addition of decorative lamination and light-reflective pigments. With the recent addition of pattern-in-product with Infused Imaging™, design options are more far-reaching than ever before.

—

The sky’s the limit with collaboration

Collaboration with our partners and inspiration from other industries have engendered the development of new technologies, products, and applications. Today, SEKISUI KYDEX is virtually everywhere, from the planes in our skies to devices in your doctor’s office.

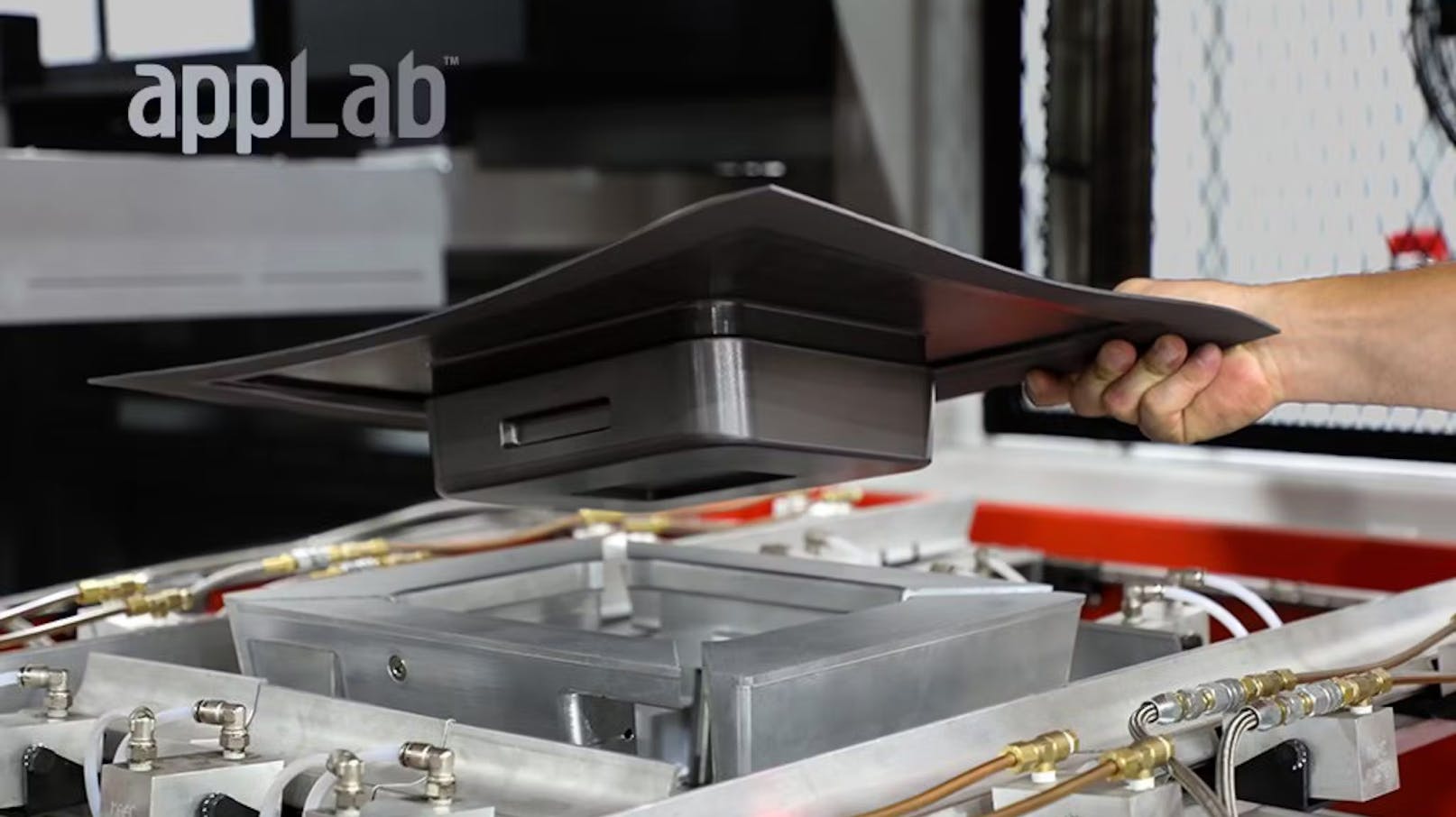

At the SEKISUI KYDEX designLab™, customers work with design and R&D teams on color and finish to begin, refine, or extend a design. Making the world safer is the focus of our FSTLab™, where we collaborate with suppliers, engineers, and end users on developing fire-resistant materials.

The first 60 years of SEKISUI KYDEX have been an inspiring journey. We’ve been most fortunate in our relationships and resources and are grateful to our customers, team members, and ownership. The future certainly looks bright for building on that legacy together for decades to come.