Methods of Thermoforming

Thermoforming shapes heated thermoplastic sheets into precise, high-quality parts with fine details and tight tolerances, offering an economical alternative to injection molding.

Thermoforming

Thermoforming is the manufacturing process of heating and shaping thermoplastic sheet to produce uniform and consistent parts with high finish specifications and tight tolerances, similar to what is expected from injection-molded parts. Fine details, including undercuts, are achieved using the economical tooling available with thermoforming.

Methods

Five primary forming processes are used for thermoplastics. Each process has distinct benefits depending on the size and detail of the part being formed.

More on Thermoforming Process

—

Advantages of Thermoforming

- Thermoforming methods allow efficient production of complex parts, part design flexibility, and precision.

- Thermoformed parts guarantee tight tolerances, seamless edges, tight corners, and precise dimensions.

- Tool design offers virtually unlimited texture and finish options.

- Single-sided molds allow for quick modifications at little cost and the ability to produce parts that fit together.

- Low machine times lead to lower lead times and lower tooling costs.

- A wide range of materials available, including sustainable choices, can be recycled or reused.

—

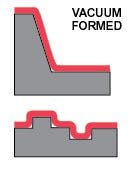

Vacuum Forming

In the vacuum-forming process, a thermoplastic sheet is heated and pulled against a male or female mold by pulling a vacuum between the mold and the sheet.

This process allows:

- Complex shapes

- Fine surface detail

- Tight tolerances

—

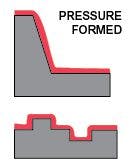

Pressure Forming

In the pressure-forming process, a thermoplastic sheet is heated and pressed against the inside of a female mold. This method uses pressure from above the sheet and pulls a vacuum between the sheet and the mold.

This process allows:

- Sharp details

- Undercuts

- Tight tolerances

- In-mold texture

—

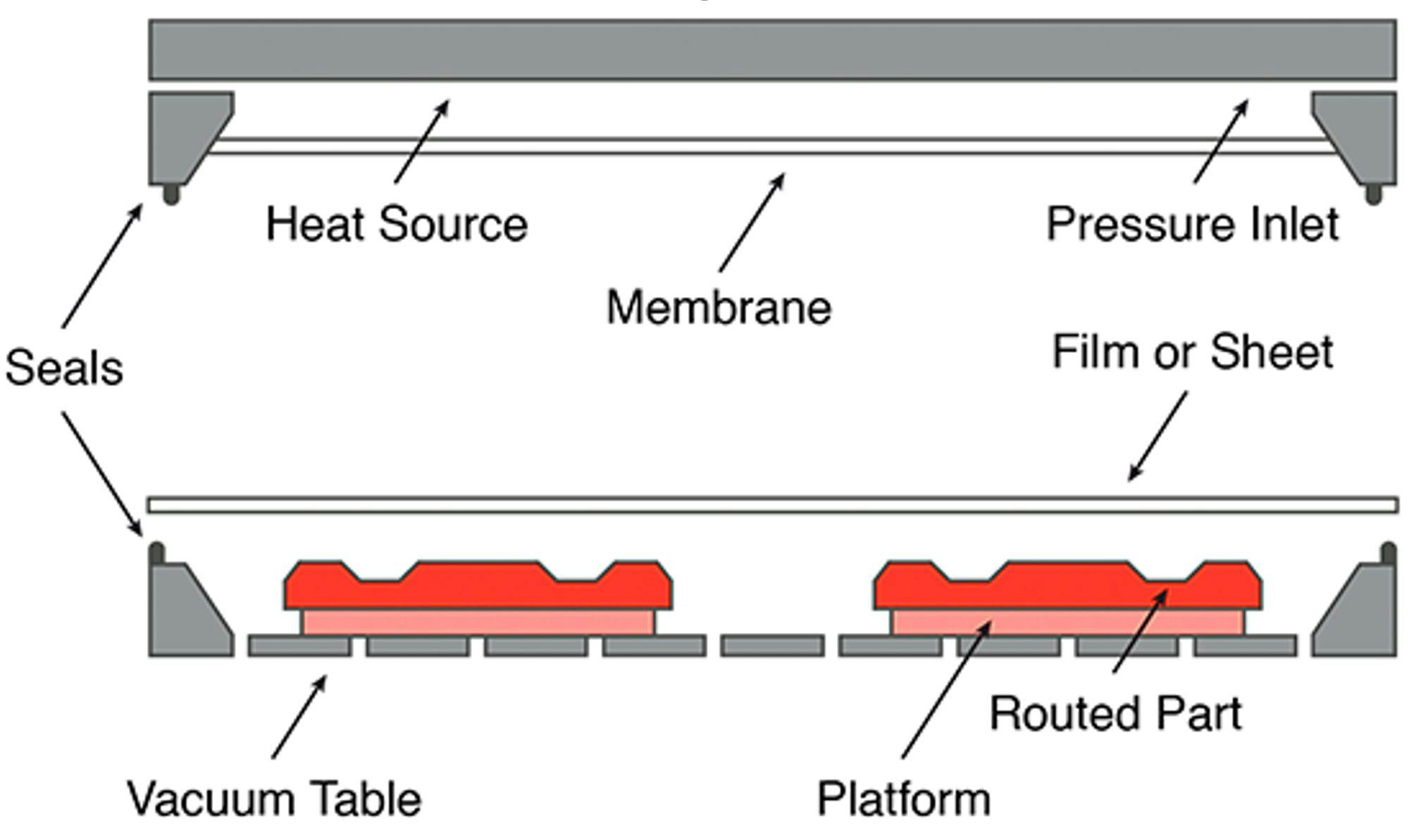

Membrane Pressing

Membrane pressing is used to encase dimensional surfaces in thermoplastics. The thermoplastic sheet is heated and vacuum-formed over the surface.

This process allows:

- Forming around the top and side surfaces

- Complex shapes

- Fine details

- Sharp or round corners

- Embossed brand logos

—

Twin Sheet Forming

The twin-sheet forming process bonds two thermoplastic sheets together to provide additional structural support and rigidity.

This process allows:

- Improved structural support

- Increased component rigidity

- Ribbing

- Surface details

- Undercuts

- Integrated hardware

- Elimination of secondary assembly

—

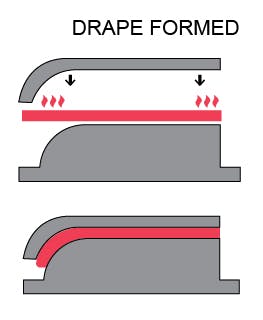

Drape Forming

Drape forming is best for simple geometries and curvatures. It involves heated thermoplastic draped over a mold to create a desired shape without the use of a vacuum. The material is heated to pliability and then draped over a tool. The tool is then clamped down, allowing the material to take the shape of the tool and cool.

This process allows:

- Consistent material thickness throughout the part

- Lower tooling costs