Why Thermoplastics are the Future

Thermoplastics are becoming the preferred choice for reducing weight and complexity while enhancing durability and sustainability in various applications.

Sustainable Solution

A variety of factors drive conversion from traditional materials to thermoplastics. As the industry looks to reduce weight, component complexity, and part counts while increasing sustainability, thermoplastics have increasingly become the material of choice.

Versatile & Durable

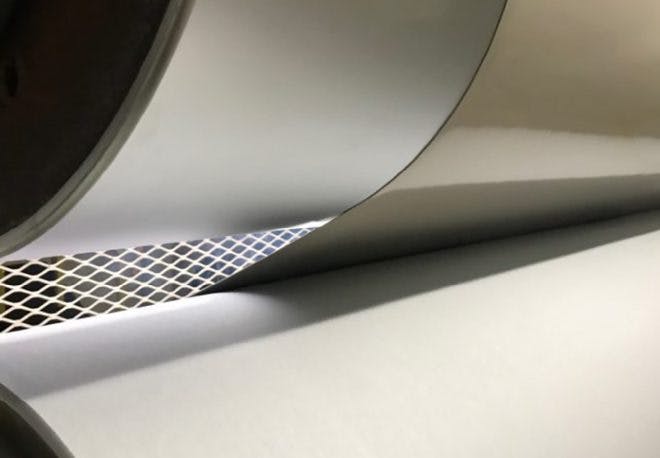

Thermoplastics offer durable and robust alternatives for housings, coverings, and surfaces. Explore how thermoplastics can be used in place of other traditional materials.

Explore Resources

Converting from Sheet Metal to Thermoplastics

SEKISUI KYDEX will help you in your journey to convert to thermoplastics over traditional materials.

Converting from Laminates to Thermoplastics

Thermoplastics provide durable aesthetic options, such as custom colors, wood grains, and surface finishes, that resist swelling, staining, and delamination from liquid exposure.

Converting from Sheet Molding Compound to Thermoplastics

Thermoplastic materials will not fray, dent, or ding, but will retain the base materials’ properties and durability, which can decrease replacement and out-of-service costs.