What are Thermoplastics?

Thermoplastics offer a unique combination of functionality, durability, and lightweight performance. This makes them ideal for industries ranging from aerospace and healthcare to consumer goods and mass transit.

Our ability to reshape them multiple times without losing structural integrity, making them a smart, sustainable choice. At SEKISUI KYDEX, we manufacture custom thermoplastic sheets that do not contain plasticizers and are tailored to meet your application’s specific design, performance, and regulatory needs.

Pliability

Thermoplastics are polymer materials that become pliable or moldable at elevated temperatures and harden after cooling. Manufacturers can shape and reform the materials without compromising integrity through this process. You can heat and cool thermoplastics repeatedly without altering their chemical structure or reducing their mechanical strength.

Due to their inherent flexibility, thermoplastics are well-suited for applications that demand durability and can adapt to any design. Manufacturers use them in housings and enclosures, medical device casings, and interior components in transportation. Thermoplastic components perform reliably while being easy to adapt to different designs.

Material Variety

Thermoplastic materials are available in a wide range of compounds, from Acrylic and ABS to high-impact plastic. Each has specific thermal and mechanical properties depending on its formulation.

For example, Acrylic provides excellent optical clarity and UV resistance, making it ideal for displays and signage. ABS offers strong impact resistance and toughness, commonly used in automotive components and consumer products. Manufacturers value engineering-grade plastic for its high impact strength and heat resistance. They often use this material in protective equipment and electronics housings.

Manufacturers can select the exact material type that meets performance standards for temperature tolerance, flexibility, flame resistance, or strength. Many of these thermoplastics are also compatible with forming techniques like injection molding or thermoforming, allowing for efficient production without sacrificing material integrity.

Thermoplastics allow manufacturers to form complex geometries without altering the base material’s properties.

Lightweight Advantage

Thermoplastic parts are usually lighter than those made from fiberglass or sheet metal. They require minimal post-processing or finishing. This reduces production time and cost.

Lighter parts mean easier handling, reduced transportation costs, and improved energy efficiency. In sectors like aviation and mass transit, every pound saved translates into fuel savings and lower emissions.

Benefits of Thermoplastics

—

Durable

Thermoplastics are ductile and can withstand high impact, making them ideal for demanding environments. Engineers design them for impact resistance, and they prove effective against dents, chips, cracks, splinters, and wear.

Their high tensile strength ensures structural integrity under repeated stress or heavy loads, reducing service calls and component replacements in even the most demanding applications.

In high-traffic settings like hospitals or schools, this durability helps facilities save on long-term maintenance costs.

—

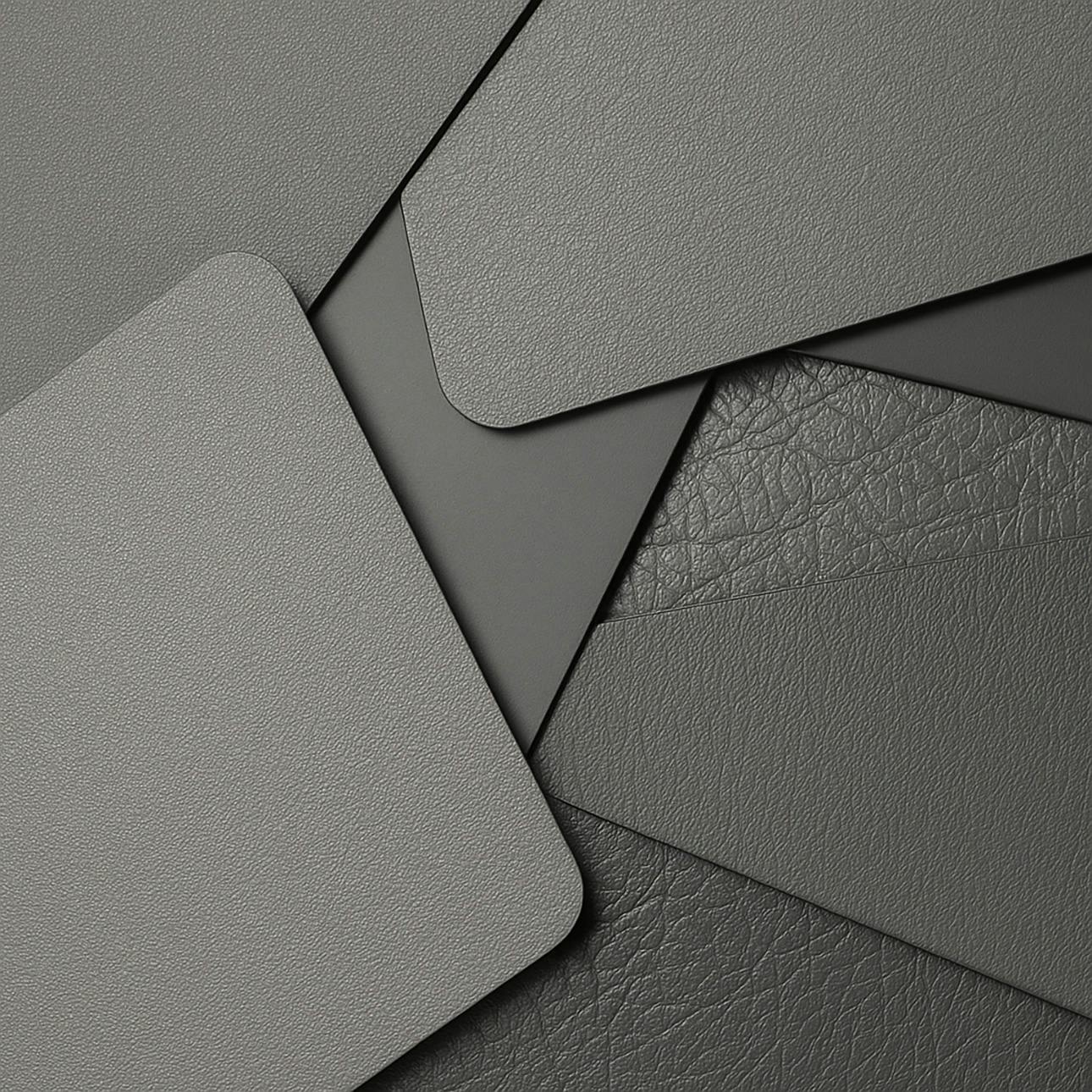

Integral Colors and Effects

At SEKISUI KYDEX, we mix color directly into the plastic material during production. This ensures a consistent finish that extends throughout the entire thickness of the product. Our through-color manufacturing approach eliminates the need for painting or surface coating. It also helps maintain appearance even after cutting, forming, or abrasion.

If you’re producing detailed parts through injection molding, this method will maintain consistency across every component. It enhances durability by preventing surface wear from exposing a different base color beneath.

SEKISUI KYDEX offers a wide variety of custom colors and finishes. These include high-gloss and matte textures, as well as metallic and patterned effects. Most thermoplastics can also be custom color matched, delivering the ideal product hue without compromising performance.

This capability is especially valuable in applications such as transportation interiors, retail displays, and consumer products. Designers keep visual consistency, branding, and wear resistance in mind when working with these thermoplastics.

—

Chemical and Stain Resistant

Our thermoplastics deliver exceptional surface durability across a broad range of environments. The majority of our material types are stain—and chemical-resistant. In addition to offering excellent abrasion resistance, we have high-performance thermoplastics. This prevents surface damage from repeated contact, friction, or rough handling.

These thermoplastics maintain their original color when exposed to industrial cleaners or harsh solvents. Certain compounds are also graffiti—and high-temperature resistant, making them ideal for outdoor and other applications.

—

Meet Codes and Requirements

SEKISUI KYDEX mixes additives into thermoplastics to meet safety standards. These standards are for smoke, fire resistance, and toxic gas release in aircraft and public transit interiors. In these regulated environments, meeting the codes for these standards is not just a preference; it’s a necessity. Many of our thermoplastic compounds are inherently tissue-friendly, which means they’re ideal for medical device applications.

—

Environmentally Friendly

SEKISUI KYDEX materials are recyclable and contain no plasticizers or VOCs, making them an environmentally sound solution. Manufacturers can often reprocess scrap material to make new products. Thermoforming manufacturing processes do not outgas VOCs or create any hazardous waste to dispose of.

Their long lifespan reduces waste and makes thermoplastics a safer choice for the environment and workplace air quality. They also support end-of-life repurposing and life-cycle design.

Ready to Start Your Project?

Whether you’re designing for durability, aesthetics or compliance, we’re ready to bring your vision to life. Trust the thermoplastic manufacturer that has the highest quality and variety of materials to meet your needs.