Why Use Thermoplastics?

Learn about thermoplastic manufacturing processes and the benefits of thermoplastics over traditional design materials.

Versatile

Thermoplastics are a plastic polymer solution used in many applications. A variety of factors are driving the conversion from traditional materials to thermoplastics.

Durable

As industry looks to reduce weight, component complexity, and part counts while increasing sustainability, thermoplastics are increasingly the material of choice.

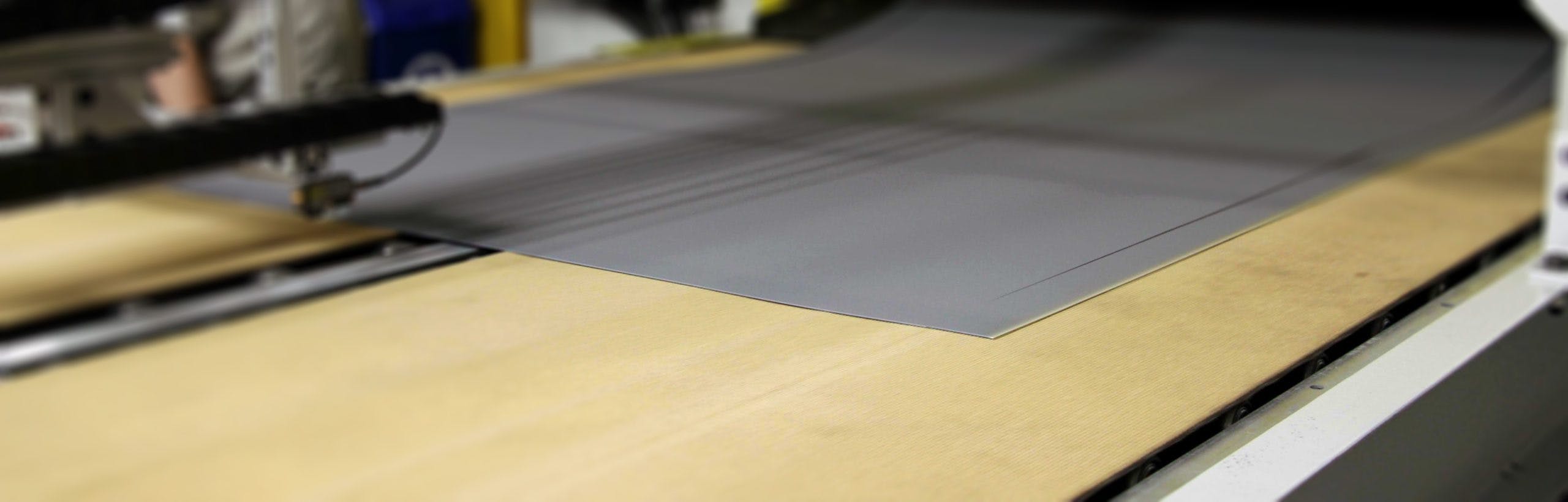

Thermoforming is a process of heating and shaping thermoplastic sheets to create precise, high-finish parts with fine details and tight tolerances.

Conversion from traditional materials such as sheet metal, laminates, and sheet molding compound to thermoplastics.

SEKISUI KYDEX thermoplastic sheets are manufactured following standards and specific formulation.

KYDEX® Thermoplastic Misconceptions

KYDEX® Thermoplastics are 100% recyclable and free of harmful additives.

Thermoplastics are the future for their their lightweight durability, reduced component complexity, and sustainability.

Answers to common questions about SEKISUI KYDEX products and our processes can be found in Product FAQs.

Product Solutions

Explore our materials for lighter, safer, stronger products with the performance and aesthetic versatility you need.